Your choice of vehicle impacts your business. The right choice can improve your fuel efficiency, safety and profitability. This guide contains advice on the features you need to consider when purchasing your next vehicle.

Ask...

What will you use the vehicle for? What load space do you need?

What conditions will it operate under?

What other legal or operational constraints apply? See:

Other requirements will affect the vehicle's configuration, including number of axles, deck length and suspension. Consider:

static rollover threshold limits – use the SRT calculator(external link) to work out the nominal SRT

the Land Transport Rule: Vehicle Dimensions and Mass 2016.

Next, consider factors that affect performance, such as engineering and vehicle components. Some of these are subject to legal requirements. See the vehicle standards you have to meet.

As a foundation, your vehicle needs sufficient power to handle the workload, using the least amount of fuel and at the lowest life cycle costs. Consider:

Also consider investment in new braking technology(external link).

You can reduce your fuel costs by:

carefully matching the engine size to the workload demand. Every additional 5hp can increase fuel consumption by 2%

fitting aerodynamic cab deflectors to help reduce aerodynamic drag and inter-vehicle spacing. These can improve fuel efficiency from at least 6% to more than 20%, depending on the body and the load

using road speed limiters or cruise control features, which can save up to 6% if set correctly

using semi-automatic and fully-automatic transmissions which now use the same or less fuel than manual transmissions.

An engine geared to run at 1450rpm at 100km/h uses approximately 4% less fuel than one geared to run at 1600rpm at the same speed.

Idling can add 20 to 30% to engine hours.

A fixed drive fan can use 10% of the engine power if it operates all the time, but may only be required for 2–5% of the time. Consider fitting electrically-driven thermostatically-controlled fans. Determine whether it is necessary for the fans to turn on automatically when the air conditioning system turns on.

At highway speeds, over half the energy required goes into overcoming aerodynamic drag. Reducing aerodynamic drag by 25% will reduce highway fuel consumption by 10–15%. Reductions in aerodynamic drag of up to 50% are achievable. However, the power-train still needs to receive sufficient cooling.

Dead insects behind the front windshield indicate an airflow problem.

Ensure your chosen vehicle meets all legal requirements under the applicable transport regulations, the Land Transport Rules and the Health and Safety in Employment Act(external link) (HSE).

Other things you need to consider:

Features that affect the normal driving of the vehicle or its driveability – the vehicle's handling, the effectiveness of the lights and cab layout.

In-service reliability, to reduce risk of a failure that could cause a crash.

Active safety features that help avoid a crash occurring – ABS, traction control and road speed limiters.

Passive safety features that protect the driver and other road users when a severe crash is unavoidable – safety belts, under-run protection and crashworthy cabs.

Driver occupational safety and health issues such as safe access into the cab, the quality of the driver's seat, cab noise, the fitting of tail lifts and other devices.

Features that increase the vehicle's visibility – for example daytime running lamps, conspicuity tape.

Features that reduce noise and emissions.

Anti-lock braking system (ABS), electronic brake stabilisation (EBS) and other brake technologies can significantly improve brake performance.

Many trucks now comply with the European ECE 29 cab strength requirements, providing added protection in head-on crashes and rolls.

Under-run protection saves lives. Some trucks are now factory-fitted with front, side and rear under-run protection.

The Health and Safety in Employment Act(external link) (HSE) recognises the cab as the driver's place of work, placing greater consideration on health and safety.

Maintenance typically makes up 5–10% of operating costs and increases as the vehicle ages or when operated in hard conditions. Choosing the right vehicle and regular maintenance will save your business more expensive downstream repairs and the cost of delayed delivery to your clients.

Ask other operators if the vehicle you're considering is reliable. Consider features that improve reliability – the use of synthetic lubricants in axles and transmissions and sealed-for-life bearings.

The amount of fuel consumed is a better indicator of engine wear and when to service your vehicle than distance travelled.

Synthetic lubricants outperform mineral lubricants at all temperatures. They can reduce fuel consumption by up to 0.5% in summer and 2% in winter.

A 15psi under-inflation of tyres will increase rolling resistance by 6%.

Keeping tyres inflated to the manufacturer's recommendations decreases the likelihood of tyre blowouts and flats.

Vehicle appearance can contribute to attracting business and retaining drivers.

Consider:

cab layouts that enhance driver comfort

vehicle styles that appeal to your clients (aggressive looking vehicles may detract)

livery that enhances your company image and inspires pride in your drivers.

Use this checklist to work out the specifications for your next vehicle.

|

Estimated total kilometres that will be travelled each year |

|

|

Types of load to be carried |

|

|

Location at which vehicle will be based (main depot or secondary depot?) |

|

|

Accessibility to loading/unloading areas |

|

|

Number of drivers who will regularly use the vehicle |

|

|

One-way or return trips? |

|

|

Expected maximum and average payload |

|

|

Average daily utilisation of the vehicle |

|

|

Average daily load factor |

|

|

Will vehicle be operating on hilly terrain, off-highway, in congestion, etc? |

|

|

Will vehicle be required to operate any additional equipment (eg Hiab)? |

|

|

Will vehicle be required to tow a trailer? |

|

|

Will vehicle stay on the same work for all its operational life? |

|

|

Will vehicle be required to comply with any specific industry sector requirements (eg tankers)? |

|

|

Type of body required to carry the load |

|

|

Load securing arrangements |

|

|

What is the best configuration for the intended task? |

|

|

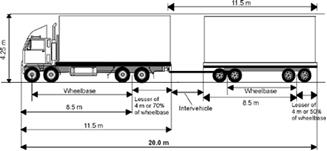

What are the expected dimensions? |

|

|

Are the weight and height limits required to comply with SRT workable? |

|

|

Is the tare mass as low as is practical? |

|

|

What are the expected axle loadings? |

|

|

What will the GVM and GCM be? |

|

|

How will the configuration affect road user charges for that vehicle? |

|

|

What types of specifications have worked best in previous operations? |

|

Is the area at which vehicle is based hilly or flat (startability)? |

|

|

How steep are the hills that the vehicle is likely to have to negotiate (gradeability)? |

|

|

Is the vehicle likely to be operated off-road? |

|

|

What is the main type of road surface the vehicle will be operating on? |

|

|

What are the temperature extremes? |

|

|

What are the prevailing winds? |

|

|

Engine option – eg fully electronic (fly by wire) |

|

|

Transmission type (synchromesh, constant mesh, non-synchromesh, automatic, automated) |

|

|

Final drive ratio |

|

|

Exhaust (the greater the back-pressure, the greater the amount of fuel used) |

|

|

Cooling fan (specify the smallest variable speed fan necessary for requirements) |

|

|

Fuel tank size (carrying excessive amounts of fuel reduces payload capacity and increases running costs) |

|

|

Radiator shutters |

|

|

Auxiliary braking (engine brake retarder – what type?) |

|

|

Type of brakes (ABS, EBS or conventional; drum vs disc) |

|

|

Running auxiliary equipment when vehicle stationary |

|

|

Speed limiting |

|

|

On-board vehicle monitoring |

|

|

Will cruise control be an advantage? |

|

|

Type of suspension (air or leaf springs?) |

|

|

Type of tyre (super single or dual?) |

|

|

Tyre tread pattern |

|

|

Central tyre pressure monitoring |

|

|

Set back or conventionally mounted front axle? |

|

|

Conventional or low maintenance hubs and bearings? |

|

|

Type of cab (full sleeper, day cab, extended cab? COE vs conventional?) |

|

|

'Dress up' equipment that improves return on investment |

|

|

Air conditioning |

|

|

Type of seating |

|

|

Will existing drivers need retraining? |

|

Brake system, including ABS, EBS, discs vs drums etc |

|

|

Under-run protection (sides, rear and front) |

|

|

Safety belts |

|

|

Conspicuity |

|

|

Cab strength under impact (to the ECE 29 standard) |

|

|

Do the mirrors provide good side and rear visibility? Should the mirrors be heated? |

|

|

Driver access to the cab |

|

|

Seat adjustment |

|

|

Driver comfort |

|

|

Cab layout |

|

|

Storage space in the cab |

|

|

Load securing provisions |

|

|

Lifting equipment such as tail lifts |

|

Service intervals |

|

|

Cost of service and parts |

|

|

Lubricants |

|

|

Service support package (if outsourcing maintenance) |

|

|

Sealed-for-life bearings |

|

|

Availability of parts |

|

|

Reliability and expected life of components |

|

|

Compatibility with other vehicles in your fleet |

|

|

Knowledge of staff undertaking the repairs |

|

|

Expected life cycle cost of maintenance |

|

Styling |

|

|

Signage |

|

|

Driver preference |

|

|

Brand promotion |

|

|

Client requirements |

|

|

Overall image |

Use the axle weights calculator to the calculate axle weights of your vehicle under various loading conditions.